LOCA:用于液体光学透明粘合剂的UV/LED树脂

从智能手机、电脑、电视机、可穿戴设备到汽车屏幕,电子产品已成为现代人的生活必备品。对于这个对环境具有重大影响的庞大行业,在设计阶段早期的原材料选择上便开始考虑可持续性问题,能够引领更大规模的可持续性实践。消费者开始寻求对环境影响更小、碳排放量更低、可回收性更高的产品,材料方面的技术进步能够提供节能、生物基成分和性能优势。

Liquid Optically Clear Adhesives (LOCA) are primarily used in the electronics industry for bonding displays to touch panels or cover lenses. They play a crucial role in devices where the clarity of the adhesive is essential for the function and aesthetics of the device, such as smartphones, tablets and touchscreen devices.

Properties of Liquid Optically Clear Adhesives

- Optical Clarity: Engineered to be highly transparent with superior light transmission capabilities. Crucial for maintaining the vividness and sharpness of display screens.

- Refractive Index: Fine-tuned to align closely with that of substrates like glass or plastic. Key to reducing optical losses from refraction and reflections at the interface where the adhesive is applied.

- Bonding Strength: Formulated to create a strong interlayer bond, significant for the structural integrity and overall tactile response of the device.

- Durability: Designed for longevity, LOCA resists environmental factors that can lead to degradation over time, such as yellowing.

- Thermal and Mechanical Properties: Absorb and dissipate stresses caused by thermal expansion or contraction as well as mechanical shocks or vibrations, which is vital for the protection of delicate display components.

- UV Curing: A characteristic feature of many LOCA formulations is their ability to be cured quickly under UV light, facilitating rapid and controlled adhesive setting during the manufacturing process. UV curing is solvent-free and low-VOC, and enables faster cycle time with lower energy consumption.

- Non-conductivity: Ensures that it does not interfere with the electrical functions of the device, maintaining signal integrity and operation.

- Gap Filling: Due to its liquid state before curing, LOCA can fill in minute gaps and surface irregularities, creating a uniform layer that supports consistent optical performance across the display.

用于LOCA的紫外线固化树脂

提供特种单体材料、低聚物材料和绝缘树脂,从而提升性能

聚氨酯丙烯酸酯低聚物

CN9021和CN9018为玻璃等材料的层压和压敏粘合剂配方提出色的粘附性和柔韧性。

产品亮点

- 卓越的光学透明度

- 低雾度

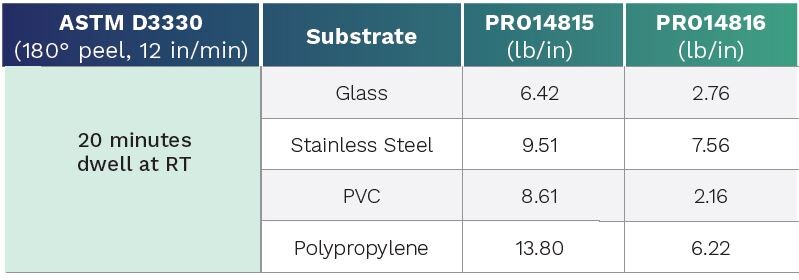

- 可出色粘附玻璃、不锈钢和其他塑料等各种基材

- 良好的防潮性能

- 高伸长率

起点配方

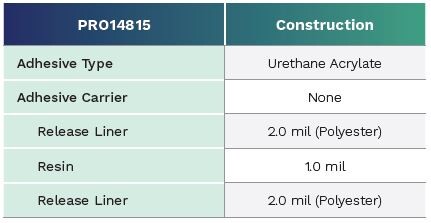

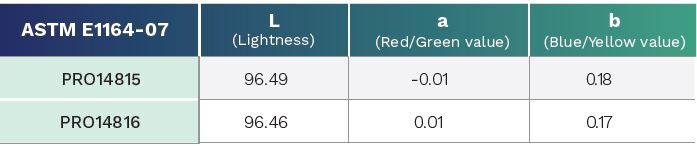

PRO14815含有76%的CN9021,PRO14816含有76%的CN9018

层压工艺

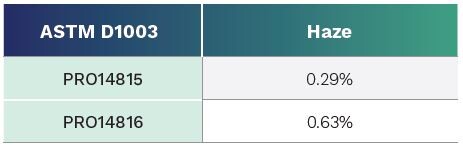

雾度

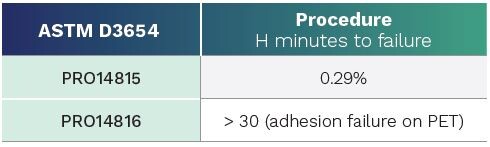

剪切强度

剥离强度

颜色

透射率

ASTM E903、D1003和E284光学透明度:97%透射率(380纳米处);99%透射率(> 400纳米处)